Warehouse Material Transportation AGV Robot with LiDAR SLAM

1000kg Capacity Wellwit Automated Guided Vehicle Robot for Industrial Transport (WS1000)

The Lidar SLAM autonomous navigation mode is adopted for rapid deployment. The equipment only needs to scan the environment to build a map and achieve accurate positioning of ± 10 mm. The load weight can be up to 1000 kg, and most goods can be transported by jacking or rotating.

- The equipment adopts the whole machine's modular design, making assembly and maintenance more convenient.

- The battery can last more than 8 hours with a full load, and the robot can automatically charge with low power (set the low power value according to the customer's requirements).

- Cluster scheduling, in the robot control system, you can view the working status, electricity, location, and other information of all robots simultaneously and schedule all devices through the system.

- Equipped with lidar safety barrier avoidance, front contact anti-collision bar, left and right emergency stop buttons, and multiple safety protection to protect equipment and cargo safety.

- Automatic path planning, realize unmanned operation, staff only need to give instructions through the control terminal.

Features

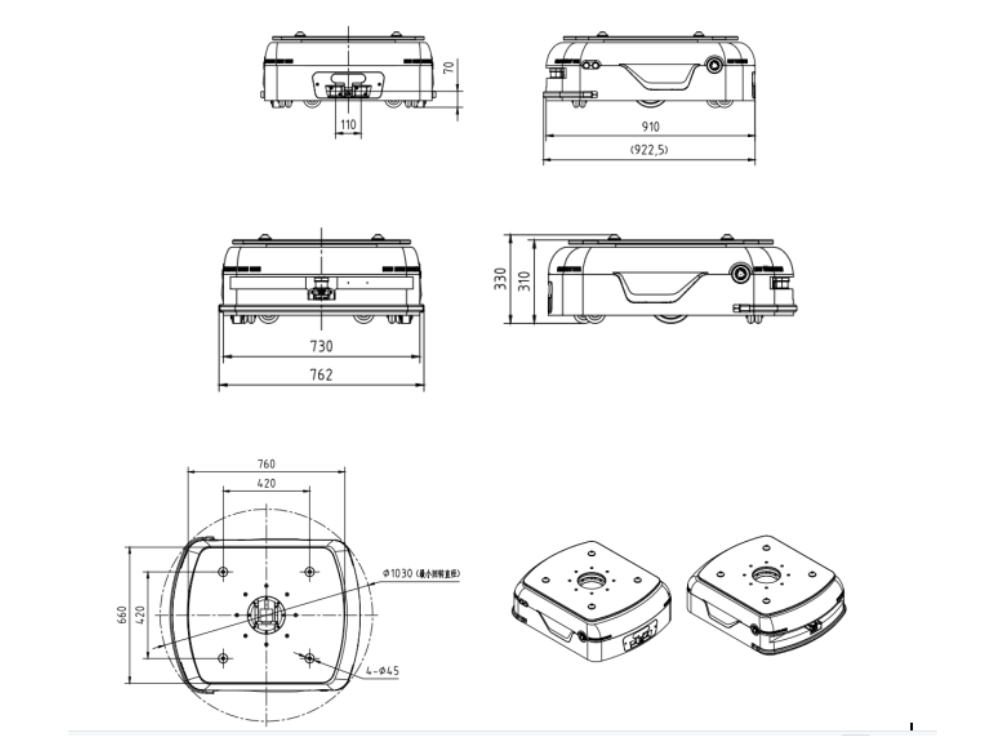

| Basic Specifications | Model | WS1000 |

| Name | Under Drive Lifting Robot | |

| Navigation | LiDAR SLAM | |

| Drive mode | Differential wheel | |

| Length, width, and height | 1000×760×310mm(exclude the bumper) | |

| Maximum payload | 1000kg | |

| Chassis ground clearance | 30mm | |

| Jacking height | 60±2mm | |

| Jacking time | 8±0.5s | |

| Network | Ethernet / Wi-Fi 802.11 a/b/g/n/ac | |

| IP rating[1] | IP 20 | |

| Range of ambient temperature and humidity | Temperature: 0~50℃ Humidity: 10~90% No compression condensation | |

| Performance | Pass ability (slope/step/gap)[2] | ≤5%/5mm/30mm |

| Navigation position accuracy[3] | ±5mm | |

| Navigation angle accuracy[3] | ±1° | |

| Operating speed (no-load / full-load) | 1.5/1.2m/s | |

| Battery | Battery specifications | 48V40AH Lithium iron phosphate |

| Endurance | 8h | |

| Charging time(10-80%) | ≤1-1.5h | |

| Charging mode | Manual/Automatic charging | |

| Battery life | 1500 cycles, capacity ≥ 80% | |

| Security | Laser number | 1 |

| Emergency stop switch | Support | |

| Speaker | Support | |

| Atmosphere light | Support | |

| Bumper strip | Support | |

| Function | Basic functions[4] | Support |

| Wi-Fi roaming | Support | |

| Follow-up function | Support | |

| Automatic charging | Support | |

| Shelf recognition | Support | |

| QR code accurate positioning | optional |

- Designed for indoor transport, not recommended for outdoor environments.

- The road surface is smooth, clean, and without significant undulations. Slope 5% = arctan(0.05) ≈ 2.8°. The robot may not stop or turn at ramps, steps, or gaps but only pass quickly perpendicularly.

- Navigation accuracy usually refers to the repeatability of the robot's navigation to the target site, and the robot can achieve the expected value of repeatability of the robot navigation from a fixed direction to the target site under the condition that the environment scanned by the robot's LIDAR is relatively stable (change rate < 30%). When the robot runs along the virtual path, it tries to fit the path as closely as possible, but repeatability is not guaranteed. The robot can guarantee to-point accuracy without guaranteeing navigation path-fitting accuracy. The minimum site spacing supported by the robot is 1 cm, so the robot cannot be used as a linear guide.

- The basic functions include map editing, model editing, positioning and navigation, API interface, etc.

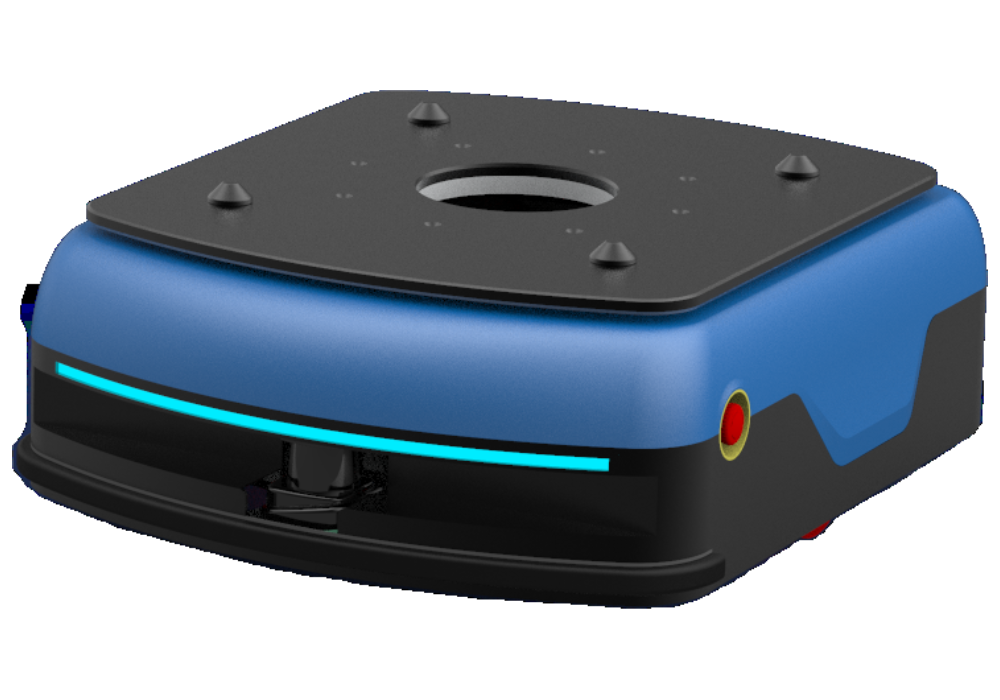

Wellwit OEM ODM Available 500kg Capacity AGV QR Code Navigation Lifting Robot (W500QR)

Using QR code navigation, laying two-dimensional code on the ground, combined with the inertial navigation system for positioning and correction, can reach accurate positioning of ± 10 mm. The load weight can reach 500kg, and most goods can be transported by jacking or rotating.

- The equipment adopts the whole machine's modular design, making assembly and maintenance more convenient.

- The battery can last more than 8 hours with a full load, and the robot can automatically charge with low power (set the low power value according to the customer's requirements).

- Cluster scheduling, in the robot control system, you can view the working status, electricity, location, and other information of all robots simultaneously and schedule all devices through the system.

- Equipped with lidar safety barrier avoidance, front contact anti-collision bar, left and right emergency stop buttons, and multiple safety protection to protect equipment and cargo safety.

- Automatic path planning, realize unmanned operation, staff only need to give instructions through the control terminal.

Features

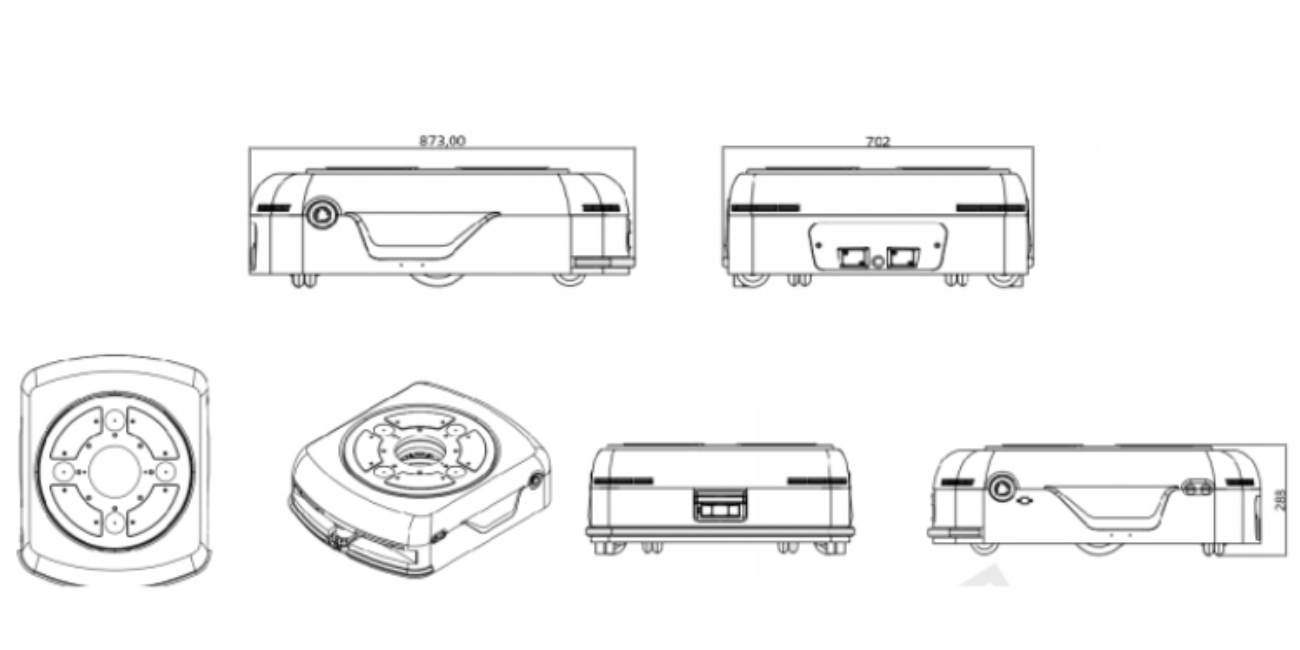

| Basic Specifications | Model | W500QR |

| Name | Under Drive Lifting Robot | |

| Deadweight | 180KG | |

| Load weight | 500KG | |

| length, width, and height | 880*680*295mm(excluded anti-crash strip) | |

| Jacking height | 60mm | |

| Navigation mode | INS+QR code or LiDAR SLAM | |

| Performance | Driving mode | Servo motor, two-wheel differential drive |

| positioning accuracy | ±5mm | |

| Maximum running speed (no load) | 1.7m/s | |

| Operating speed (full load) | 1.0m/s | |

| Charging mode | Automatic charging / offline charging optional | |

| Endurance time | ≥ 8H | |

| Battery | Battery type | Lithium battery 48V |

| Battery capacity | 40AH/30AH | |

| Charging time | 1.5~2H | |

| Battery life | 1500 cycles, capacity ≥ 80% | |

| Security | Obstacle avoidance | Lidar obstacle avoidance, contact anti-collision strip |

| Audible and visual alarm | Support | |

| Emergency stop switch | Support, one on each side | |

| Communication mode | WiFi | |

| Debug interface | Interface is open |

Company Profile

Shenzhen WellWit Robotics Co., Ltd was established in Shenzhen in March 2015, our company focuses on research and development of mobile robot. The R&D team consists of members who experienced in field of robot, embedded hardware, software, algorithms, artificial intelligence, etc.

Currently, products for sale including moving robot, sorting robot, Auto-forklift, etc. Navigation method we provide including QR code navigation, LiDAR SLAM navigation, Visual SLAM Navigation, RTK navigation.

We focus on providing custom logistic robots for the integrators who focus on Intelligent Logistics and Intelligent Factory, and provide AGV&AMR with ODM/OEM service for global clients.

-750x750w.jpg)

-750x750w.jpg)

-750x750w.jpg)